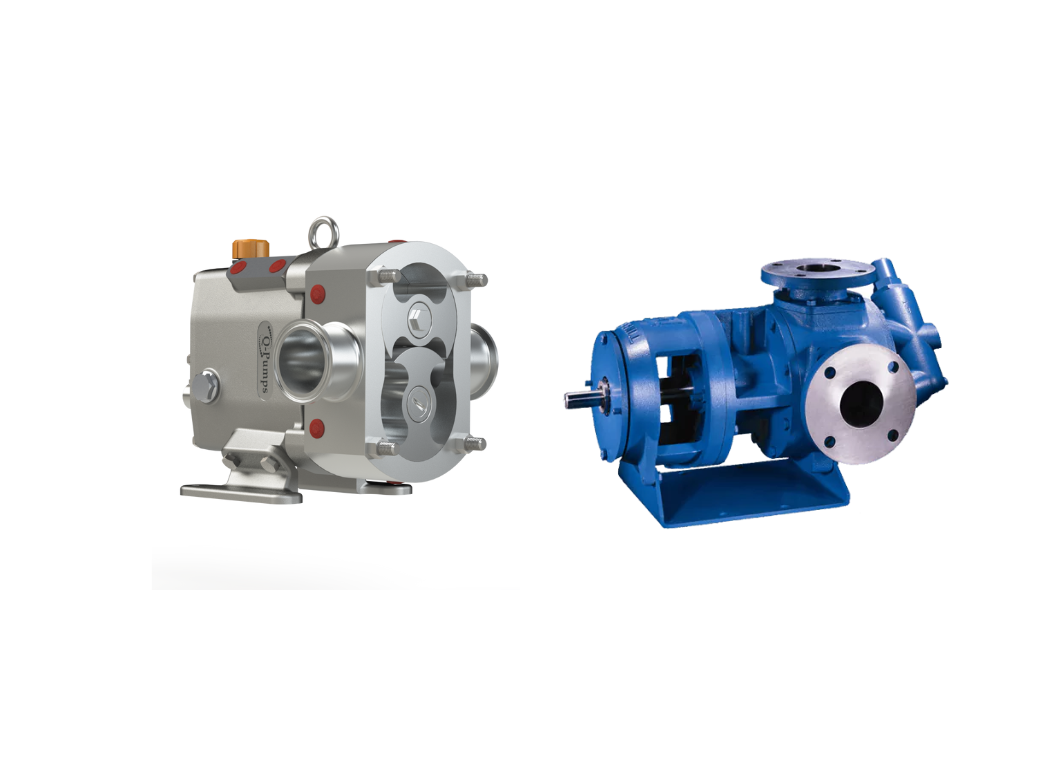

Discover the key differences between a lobe pump and a gear pump, and learn why the QL Series from Q-Pumps is the ideal solution.

In industrial fluid handling, selecting the right pump technology is crucial for efficiency, product integrity, and maintenance savings. One of the most common comparisons made by engineers and plant managers is lobe pump vs gear pump. Both technologies have their advantages, but the differences can significantly impact performance depending on the application. In this article, we’ll break down how each pump works, their benefits and limitations, and why the lobe pump, specifically the Q-Pumps QL Series, stands out as a superior choice in various industries.

How Does Each Pump Work?

Lobe Pump Operation

Lobe pumps are a type of positive displacement pump in which two or more lobes rotate within the pump chamber. These lobes do not make contact, allowing for gentle handling of fluids, which is critical in hygienic or shear-sensitive applications. The rotation of the lobes creates expanding volume on the suction side, drawing in fluid, and reducing volume on the discharge side, pushing the fluid out efficiently.

Gear Pump Operation

Gear pumps operate by using two meshing gears to transfer fluid. As the gears rotate, fluid is trapped between the gear teeth and the casing and moved around the outside of the gears from the suction to the discharge side. This design is ideal for high-pressure applications but can be less gentle on the fluid and prone to wear if particles are present.

Lobe Pump vs Gear Pump

When comparing lobe pumps vs gear pumps, several technical and practical differences arise that can determine which pump is best suited for your operation.

Efficiency and Pressure Handling

Gear pumps generally handle higher pressures more efficiently than lobe pumps. However, lobe pumps compensate by excelling in low to medium pressure systems that require precision and product integrity.

Fluid Sensitivity and Shear

Lobe pumps offer a clear advantage in handling shear-sensitive or particulate-laden fluids. Since the lobes do not touch, product damage is minimized. Gear pumps can shear fluids and damage particles due to tight tolerances and gear contact.

Maintenance and Durability

Lobe pumps are easier to clean and maintain, especially in sanitary applications. Gear pumps, while more compact, can wear out faster if solids are present in the fluid.

Why Choose the Q-Pumps QL Series?

Q-Pumps’ QL Series lobe pumps are engineered to deliver hygienic, efficient, and reliable performance for a range of industries including food, beverage, pharmaceuticals, and cosmetics. Their stainless-steel construction, CIP/SIP capabilities, and modular design make them a standout option.

Key Features of the QL Series

- Hygienic design compliant with 3-A and EHEDG standards

- Capable of handling viscous and shear-sensitive fluids

- Compact, modular design for flexible installations

- Reversible operation and wide flow range

- Easy maintenance and cleanability

Applications of the QL Series

From dairy products and juices to pharmaceuticals and creams, the QL Series adapts to various process needs. Its precision and gentle pumping mechanism help protect product texture and quality during transfer.

Optimize Your Process with the QL Series

Whether you’re upgrading an existing system or designing a new one, the QL Series offers a dependable, cost-effective solution.

Know more about QL Series

Need help selecting the right lobe pump for your application? Contact our team today and discover how Q-Pumps can improve your process efficiency.

Get a customized lobe pump quote today