Discover the benefits of a sanitary pump for moisturizing creams in the personal care industry.

Moisturizing Creams in Personal Care

The personal care, cosmetics, and beauty industry offers a widely used product found in nearly every household: moisturizing cream. Over the past century, advances in technology have allowed moisturizing creams to be available in various forms, tailored for different needs and users. Throughout history, skincare has played an important role in health and wellness, as seen in ancient cultures.

History of Moisturizing Creams

The origins of moisturizing creams can be traced back to ancient civilizations using natural products to hydrate and protect the skin. Around 3000 B.C., Egyptian royalty used seed and castor oils for this purpose. In 1000 B.C., Greeks used honey and molasses mixed with milk, and Romans later added herbs and floral oils. Roman physician Galen developed an early cream using beeswax, rose oil, and water around 200 B.C.

The formulation continued to evolve with almond oil and other natural fats. In the 19th century, petroleum jelly and mineral oils were added for consistency. In 1900, Hinds introduced an almond-based cream that gained popularity with the rise of the cosmetics industry.

The first scientifically developed facial cream was created by chemist Max Huber, named La Crème de la Mer, incorporating minerals and oils through a biofermentation process that took four months to enhance regenerative and anti-inflammatory properties.

Huber's technique inspired future formulations in the personal care industry, leading to a variety of moisturizing products with unique ingredients and purposes.

How Moisturizing Creams Are Made

Moisturizing creams are emulsions—mixtures of oil and water—created in two main phases:

- The oil phase: Dry-soluble ingredients are mixed with mineral or silicone oils.

- The aqueous phase: Water is blended with emulsifiers and thickeners.

These phases are then emulsified under continuous pumping and agitation to achieve the desired creamy texture. Finally, active ingredients are added.

Due to variations in ingredients, formulas, and viscosities, the production process must be adaptable and precise.

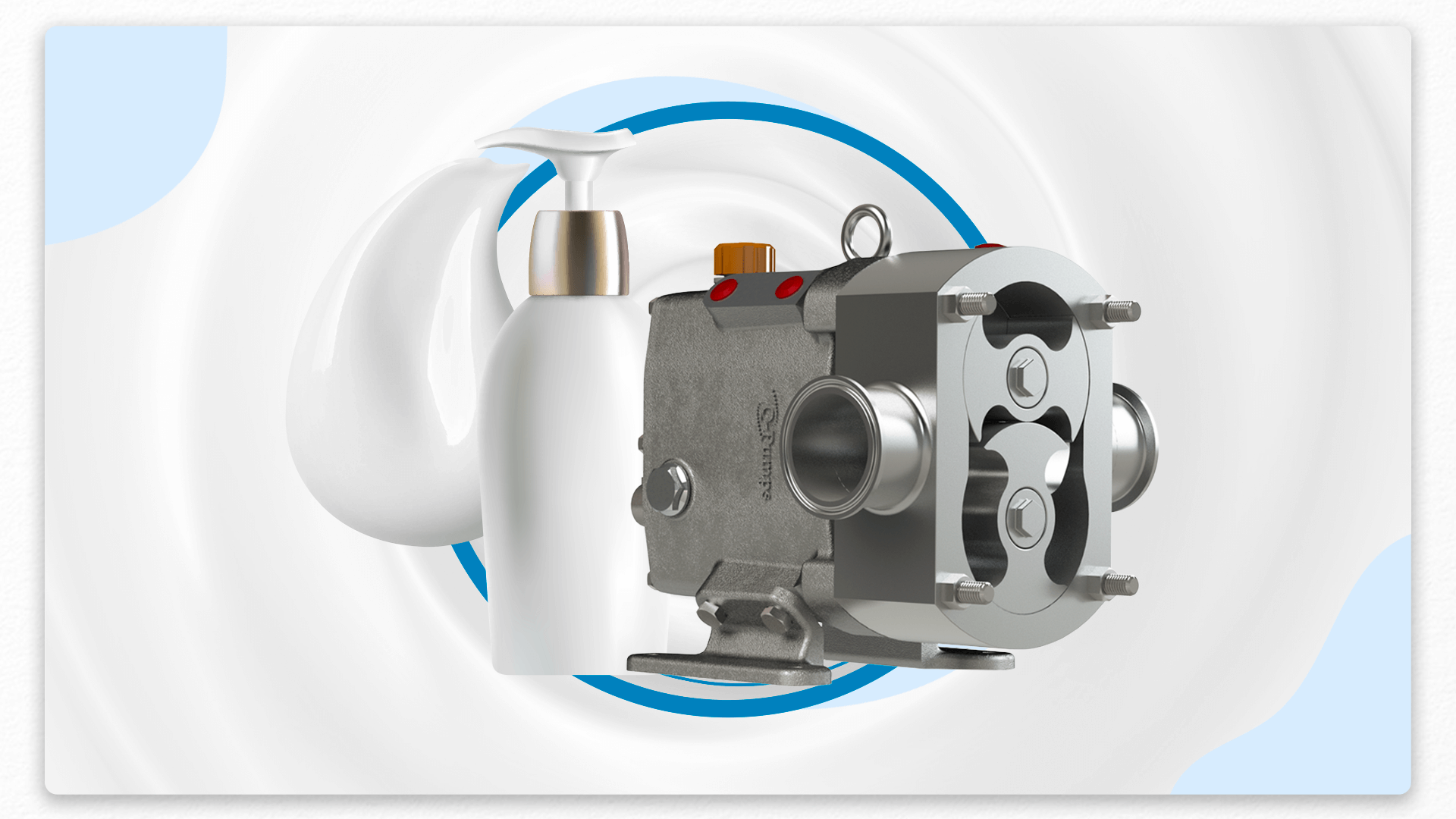

Sanitary Pumping Solution for Moisturizing Creams by Q-Pumps

Q-Pumps® offers reliable solutions for pumping body and facial creams. The QL series lobe pump is built with high-quality, durable materials to handle flow rates up to 441 GPM (1,670 LPM) and discharge pressures up to 290 psi (20 bar).

Features of the QL Series Pump

This positive displacement pump can handle products with viscosities up to 1,000,000 cP, suction capacities up to 4 meters, flow rates up to 100 m³/hr, and heads up to 250 meters. It is known for its durability and competitive pricing.

Key features include:

- Four seal options for different applications

- Standard seal material: Tungsten Carbide vs. Tungsten Carbide

- Thermal jackets on the front cover and casing

- Various connection options

- Bearing housing available in cast iron or stainless steel

- Clean-In-Place (CIP) compatibility

The pump allows for quick maintenance and cleaning by removing only the front cover. Rotors and seals are accessible without dismantling the entire process line.

Advantages of the QL Pump

- Front access enables faster cleaning and reduces downtime

- Thermal jackets help maintain optimal temperature control

- Competitively priced without sacrificing performance

- Versatility for abrasive and specific product applications

Certifications of the QL Pump

The QL pump complies with international sanitary standards, including 3-A Sanitary Standards, Inc. (3-A SSI), ensuring equipment hygiene in food, beverage, and pharmaceutical applications. Q-Pumps holds certificates 1004 and 1805.

Know more about QL Series

Get in Touch With Us

Let us support your production goals with a customized sanitary pumping solution.

Request free technical consultation