Discover the advantages of QTS pumps compared to progressive cavity pumps for sanitary fluid handling applications.

Choosing the right pump for sanitary applications in industries such as food, beverages, cosmetics, and pharmaceuticals is essential to ensuring product quality, process efficiency, and low operating costs. In this article, we compare two commonly used positive displacement pumps: the QTS twin screw pump and the progressive cavity pump. While each has distinct advantages, the QTS pump stands out for its versatility and hygienic design.

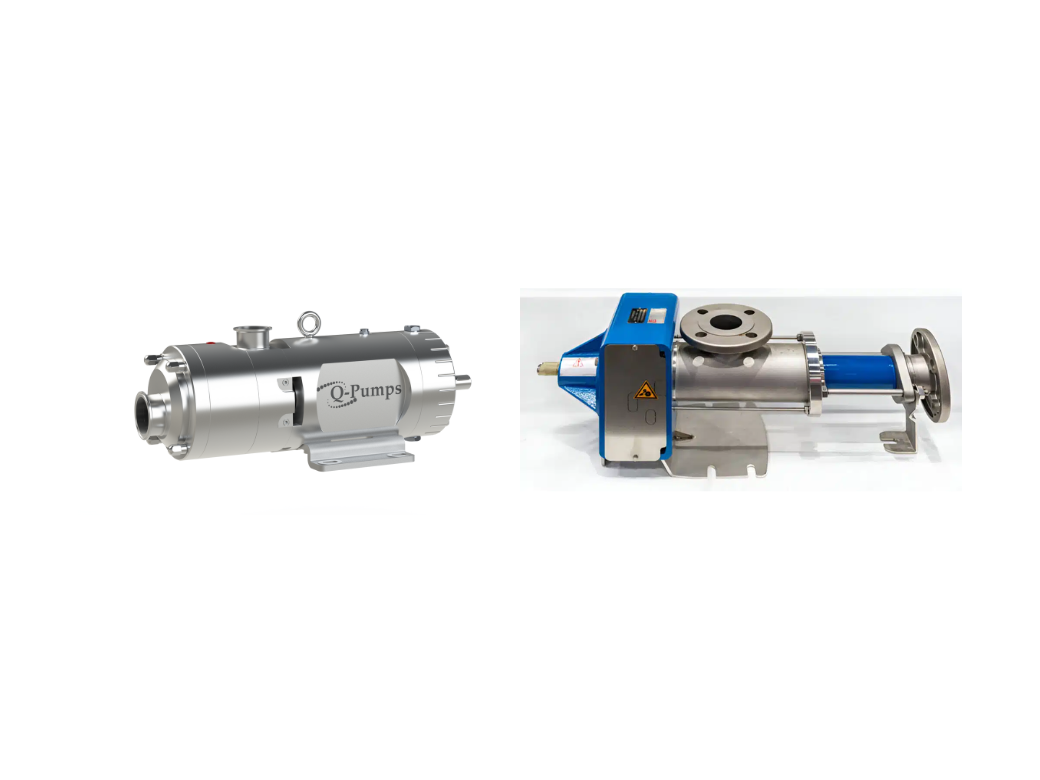

QTS Pump Overview

The QTS series from Q-Pumps is a sanitary twin screw pump designed for handling high and low viscosity fluids with solids, offering gentle product handling and superior hygienic performance. Its double screw design allows it to function both as a process pump and a CIP (Clean-In-Place) pump, reducing the need for separate equipment and increasing plant efficiency.

Progressive Cavity Pump Overview

Progressive cavity pumps operate using a rotor and stator mechanism that displaces product in continuous, sealed cavities. These pumps are known for handling viscous fluids and slurries with high efficiency and minimal shear, making them suitable for many industrial applications.

QTS Twin Screw Pump Compared to Progressive Cavity Pump

Key Differences: QTS vs Progressive Cavity

To better understand how these two pumps compare, let’s examine their performance in critical areas:

- Hygiene and Cleanability: The QTS pump offers a fully sanitary design, EHEDG and 3-A certified, and is ideal for CIP/SIP. Progressive cavity pumps require disassembly or external CIP systems.

- Handling Solids: QTS handles solids gently thanks to its twin screw design, while progressive cavity pumps may damage solids or suffer wear.

- Maintenance and Downtime: QTS has fewer wear parts and is easier to clean and maintain. Progressive cavity pumps often require stator replacement.

- Dual Functionality: QTS functions as both a process and CIP pump. Progressive cavity pumps typically require a separate CIP system.

- Flow and Pressure: QTS supports a wide flow range (up to 300 GPM) and pressures (up to 300 psi). Progressive cavity pumps vary based on rotor/stator design.

- Versatility: QTS is ideal for a wide range of viscosities (1 to 1,000,000 cP). Progressive cavity pumps perform well with viscous products but are limited in cleanability.

Which Applications Benefit Most from Each?

The QTS pump is perfect for applications where hygienic design, product integrity, and CIP capability are priorities—such as dairy, sauces, pharmaceuticals, and cosmetics. Progressive cavity pumps, on the other hand, may be better suited for abrasive, non-hygienic, or high-viscosity applications where cleanability is less critical.

Why Choose the QTS Pump Over a Progressive Cavity Pump?

In addition to sanitary design and dual functionality, QTS pumps offer high reliability, easy maintenance, and long-term cost savings. They also minimize downtime due to fewer moving parts and faster cleaning cycles. For industries focused on hygiene, safety, and product quality, the QTS pump is a future-proof investment.

Take Your Process to the Next Level

If you're looking for a hygienic pump solution that offers maximum flexibility, low maintenance, and superior performance, the QTS twin screw pump is the right choice. Contact us today to learn more about how QTS can optimize your process and meet your production goals.

| Request free technical consultation |