Discover how Q-Pumps' sanitary industrial pumps optimize the production of liqueurs and spirits worldwide.

Understanding the Difference Between Spirits and Liqueurs

In the alcoholic beverage industry, distinguishing between spirits and liqueurs is essential. Spirits are distilled beverages with high alcohol content, produced by fermenting and distilling ingredients like grains, potatoes, or fruits. Examples include whiskey, vodka, tequila, and rum. Liqueurs, on the other hand, are spirits sweetened with various flavors, oils, or extracts, resulting in a lower alcohol content. Popular liqueurs include amaretto, limoncello, and coffee liqueur.

Global Consumption Trends of Spirits and Liqueurs

According to the World Health Organization, over half of the population in regions like Europe and the Americas consume alcohol. Spirits account for approximately 44.8% of the total recorded alcohol consumption globally, while beer follows at 34.3%. The demand for diverse alcoholic beverages underscores the need for efficient and hygienic production processes.

Q-Pumps®: Enhancing Alcoholic Beverage Production

Q-Pumps® specializes in designing and manufacturing industrial pumps tailored for various applications in the alcoholic beverage industry, including the production, handling, and mixing of spirits and liqueurs.

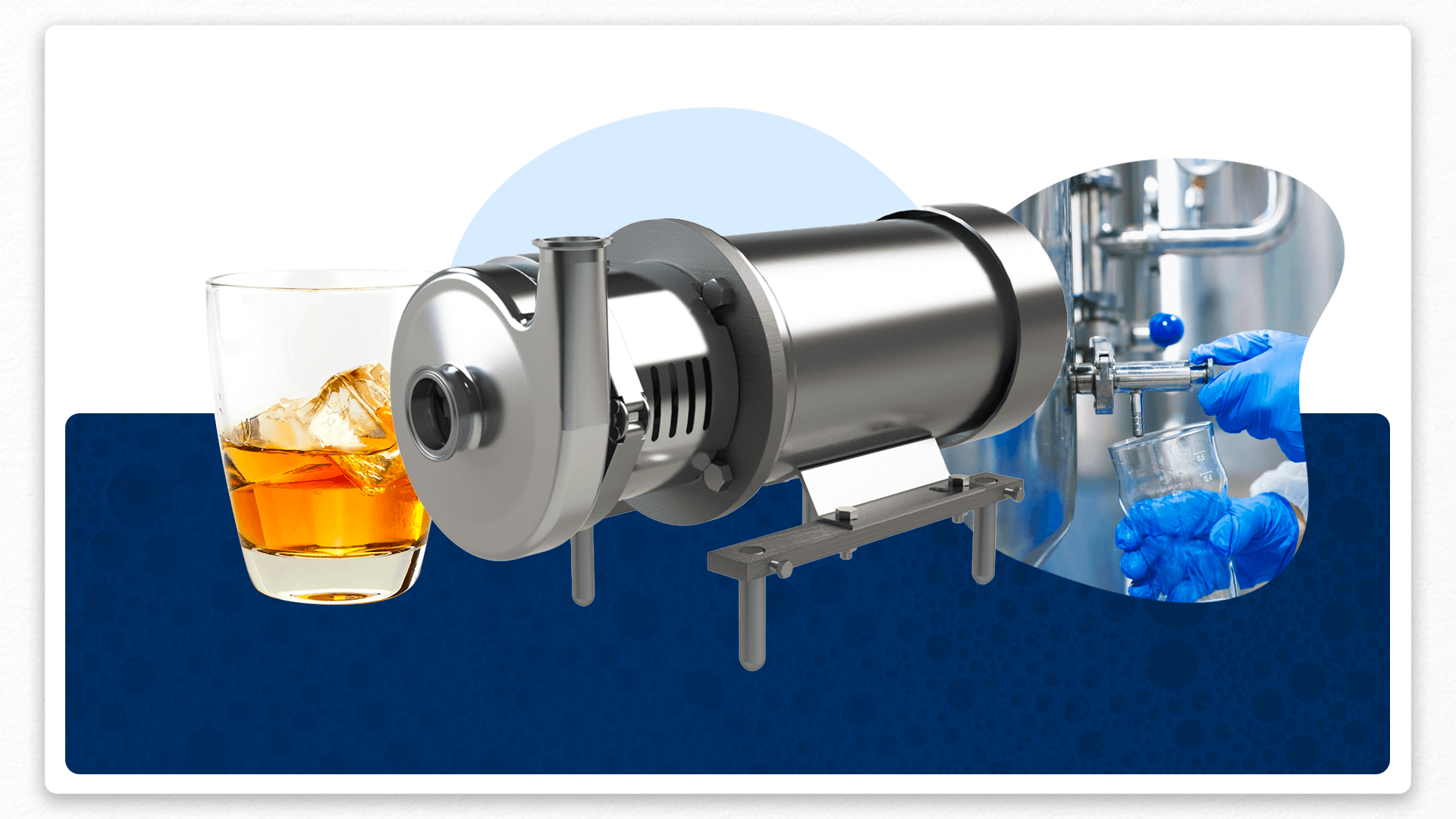

QC Series: Optimized for Sanitary Applications

The QC Series centrifugal pumps are engineered to handle flows up to 1,200 GPM and pressure loads up to 270 feet. Key features include:

- Open impeller design

- Volute casing with center suction

- Standard clamp connections, with options for flange, NPT, weldable, Bevel Seat, DIN, and SMS

- Stainless steel support set and legs

- Compatibility with both 60 Hz and 50 Hz frequencies

- Stainless steel adapter

- All product-contact parts made of T316L stainless steel

Benefits of the QC Series

- Enhanced impeller support using a wedge and nut mechanism

- Improved long-term efficiency

- Ability to upgrade a standard QC pump to a QC Plus with a conversion kit

Certifications Ensuring Quality and Hygiene

The QC Series pumps hold international certifications, including:

- 3-A Sanitary Standards, Inc. (3-A SSI) certifications 1004 and 1805

- European Hygienic Engineering & Design Group (EHEDG) certification

Applications in the Alcoholic Beverage Industry

Q-Pumps' sanitary pumps are integral to various stages of alcoholic beverage production:

- Fermentation: Ensuring consistent mixing and temperature control

- Distillation: Handling high-temperature liquids safely

- Flavoring: Precise addition of flavoring agents

- Bottling: Maintaining hygiene during the final product transfer

Why Choose Q-Pumps for Your Production Needs

Selecting Q-Pumps' sanitary industrial pumps offers several advantages:

- Compliance with international hygiene standards

- Durable construction suitable for various alcoholic products

- Customizable options to fit specific production requirements

- Expert support and consultation services

Contact Q-Pumps for Tailored Solutions

Enhance your alcoholic beverage production with Q-Pumps' reliable and hygienic pumping solutions. Visit our website to learn more about the QC Series and how we can assist in optimizing your processes.

Learn More About the QC Series

Request free technical consultation

Partner with Q-Pumps to elevate your production standards and meet the growing global demand for high-quality spirits and liqueurs.